DESIGN & PRODUCTION OF ROPEWAYS

ASSESMENT

EXECUTIVE PLANNING & LINE DESIGN

Every ropeway system begins with a rigorous project planning and line design process, where our engineering team translates topographical data, client needs, and regulatory parameters into a fully defined system. Using industry-specific software and geospatial modeling, we calculate line geometry, anchoring points, vertical elevation gain, load distribution, and travel capacity.

Key engineering decisions made at this stage include:

- System type (ski lift, chairlift, jig-back, funicular, aerial tram, etc.)

- Number and spacing of towers

- Drive station configuration (valley vs. summit)

- Tensioning and return systems

- Rope diameter, speed, and vehicle frequency

Each ropeway is designed not just for function, but also to respect the environment, terrain, and client operating model — whether for tourism, ski resorts, urban mobility, or utility transport.

IN-HOUSE ENGINEERING & PROJECT DEVELOPMENT

Graffer’s core strength lies in its internal technical department, staffed with civil, mechanical, and electrical engineers specialized in ropeway systems. This enables us to deliver not only precision design and compliance calculations, but also to iterate quickly with clients, adapting the solution in real time to site conditions or regulatory feedback.

Our team develops:

- Preliminary and executive designs

- Structural calculations for towers and foundations

- Electromechanical layout and load simulations

- Safety system integration according to ANSFISA, D.M. 203/2015, and EU Reg. 2016/424

- Full documentation for public approval and certification

Clients benefit from a single point of contact, a centralized digital project, and constant communication with our engineering office throughout the lifecycle of the project.

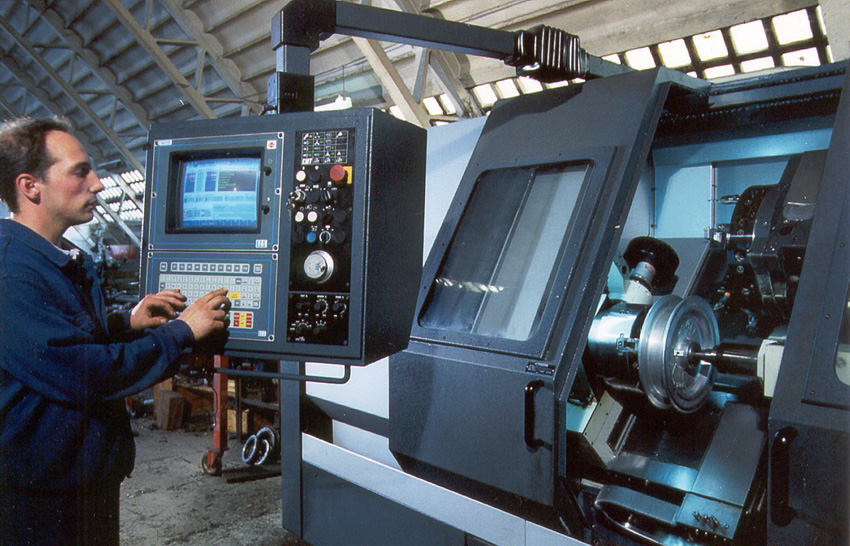

INTERNALIZED STEEL FABRICATION & CARPENTRY

In 2025, Graffer expanded its vertical integration by acquiring a steel welding and industrial carpentry company, allowing us to internalize the production of core mechanical components. This investment has significantly improved our quality control, lead times, and production capacity for large-scale and custom installations.

Fabrication capabilities include:

- Tower shafts and anchor flanges

- Steel platforms and access walkways

- Station base frames and enclosures

- Service ladders, guard rails, and cable guides

- Vehicle suspension structures (chair arms, baskets, brackets)

Every piece is built to CE certification standards, traceable, and compliant with structural integrity requirements for mountain and urban environments. The workshop is equipped with CNC tools, robotic welding, and advanced treatment systems for corrosion resistance and finish quality.

COMPONENTS PRODUCTION & OUTSOURCING STRATEGY

While most large-scale steel components are now produced internally, Graffer maintains a network of certified European suppliers for specialized parts and proprietary systems — ensuring the highest quality and interoperability of the ropeway as a whole.

These components include:

- Cable grips and grip testers

- Bullwheels and sheave assemblies

- Hydraulic tensioning units

- Redundant brake systems

- Control panels and safety relays

- Passenger carriers (seats, cabins, T-bars)

This hybrid strategy — core manufacturing in-house, with strategic outsourcing for high-precision parts — enables Graffer to combine full vertical control with access to the latest innovations in materials and automation.

QUALITY CONTROL & FINAL ASSEMBLY

Once the structure and mechanical systems are completed, we proceed to pre-assembly and dry testing within our facility. This critical phase allows our team to detect and resolve potential integration issues before components are sent to the field — reducing on-site assembly time and minimizing weather-related delays.

Activities include:

- Partial or full tower assembly

- Drive station motor and gearbox alignment

- Control cabinet programming and bench testing

- Rope path simulation and guide testing

- Painting, galvanization, and surface protection

- Packing and logistical planning for site shipment

Each system is shipped with a unique assembly checklist, QR-linked component map, and technician briefing for field deployment.

INSTALLATION, TESTING & COMMISSIONING

Installation is performed by Graffer’s field teams, specialized in mountain environments and high-altitude logistics. We coordinate transport, lifting (via crane or helicopter), anchoring, and the complete mechanical and electrical integration on-site. Once installed, our engineers carry out the final commissioning procedures, including safety simulations and official testing.

Key operations:

- Tower and station installation

- Rope stringing, tensioning, and magnetic inspection

- Brake calibration and emergency stop test

- Operator training and system orientation

- Certification in collaboration with national authorities

- Final delivery of logbooks and CE documentation

With over 2,000 systems delivered and a reputation for precision, Graffer ensures each ropeway is safe, compliant, and optimized for decades of operation.

CONCLUSION

Graffer’s vertically integrated design and production process ensures that every ropeway system is engineered with care, manufactured with precision, and delivered with confidence. From in-house calculations to full-scale fabrication, we combine flexibility, speed, and technical depth — backed by over 85 years of experience.