OUR MAIN REFERENCES

From high-altitude lifts to service ropeways and urban funiculars ; Graffer’s Installations are operating across Europe with certified reliability.

Extraordinary Maintenance of the GRAN SASSO Cable Car

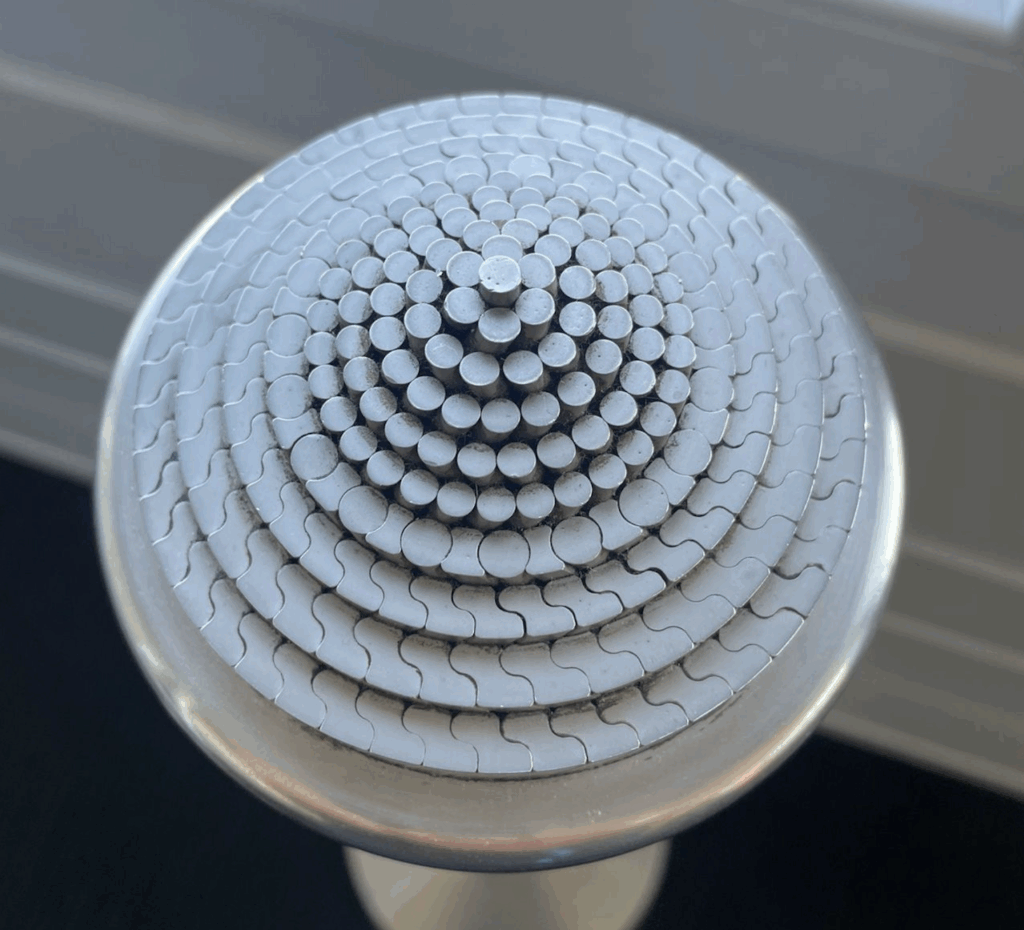

The extraordinary maintenance work for the replacement of the 4 carrying ropes of the bi-cable “Fonte Cerreto – Campo Imperatore” cable car, located in the Municipality of L’Aquila, was successfully completed in July 2025. The project, carried out by GRAFFER Srl, formed part of the necessary regulatory adjustments in compliance with EU Regulation 2016/424 and the applicable technical standards EN12927. The new ropes, each with a diameter of 57 mm, were manufactured using advanced pre-formed stranded wire technology, offering lower tension, greater wear resistance, targeted lubrication, and full traceability via copper wires and integrated visual markers. The scope of work also included the supply of anchoring materials, coil protection during transport and installation, preparation of the operation and maintenance manual, and submission of all required documentation for ANSFISA clearance.

The project involved exceptional transport and storage of the ropes, high-altitude work site setup, controlled dismantling of the old ropes, and installation of the new ones using 200 kN and 120 kN winches. Activities such as rope pulling, connection, tensioning, and anchoring were followed by magneto-inductive testing, thorough safety inspections, and final testing conducted in the presence of the relevant authorities. The entire intervention was completed ahead of schedule, thanks to optimized logistics and the expertise of highly specialized personnel in ropeway systems and high-altitude operations.

Overhaul of the TRAPANI-ERICE Cable Car

The twentieth year general overhaul of the WC02 Trapani–Erice cable car, an automatic clip-on system with eight-seat cabins located in the Municipality of Erice (TP), was successfully completed in July 2025, marking the second phase of a project spanning from 2024 to 2026. The intervention involved extensive mechanical, electromechanical, structural, and electrical works, carried out in full compliance with D.M. 203/2015 and relevant European sector regulations.

Key activities included the replacement and overhaul of critical components such as gear reducers, motors, brakes, rollers, and vehicles, alongside comprehensive non-destructive testing (NDT). The system’s electrical control, supervision, and safety systems were modernized, and the carrying-hauling rope was successfully replaced. New electrical panels, PLCs, supervision systems, selective safety circuits, and hydraulic control units were also installed to enhance system performance and reliability.

In addition to the technical interventions, the project included full design and testing services, training of operational personnel, issuance of CE certifications, updates to technical manuals, and implementation of remote assistance capabilities. This comprehensive overhaul preserved the original infrastructure layout, ensuring continuity of public transport service while significantly improving the efficiency and safety of the cable car system.

Overhaul of the CHIAIA-NAPOLI Funicular

The twentieth year overhaul and modernization of the Chiaia Funicular was successfully completed in January 2025, following an extensive program of structural and safety upgrades. The intervention included non-destructive testing (NDT) in accordance with UNI EN ISO 9712:2022 standards, along with the inspection and restoration of vehicles, rope checks, issuance of static certifications, fire safety inspections, track recalibration, and updates to the grounding and lightning protection systems. Renovation works were also carried out at the stations, involving machine rooms, maintenance pits, railings, signage, staff facilities, and passenger information systems.

The funicular infrastructure underwent a complete modernization, including the full replacement of bullwheels, sheaves, tracks, and drive systems, to support increased passenger capacity and meet the requirements of NTC 2018 standards. New electrical and mechanical systems were installed, such as UPS units, motors, brakes, hydraulic units, video surveillance, intercom, and sound distribution systems. The control system was upgraded to a digital, automated platform with remote monitoring and enhanced emergency management functions.

The vehicles underwent major refurbishment, including the replacement of pantographs, overhaul of braking systems, renewal of wheels and suspensions, installation of new maintenance hatches, and integration of high-durability door-opening mechanisms. To ensure safety during construction, certified fall protection systems, modular fences, temporary walkways, and fire safety equipment were installed.

The project was finalized with the delivery of the executive design, required certifications, and complete “as-built” technical documentation, ensuring a significant improvement in the reliability, efficiency, and safety of this critical public transport system in Naples.

Overhaul of the Tasso Monte Crucio–CAMIGLIATELLO Cable Car

Twentieth year General Overhaul of the VC01 “Tasso – Monte Curcio” Cable Car

Completed as part of the 2022–2024 Three-Year Public Works Program, the twenty-year overhaul of the VC01 “Tasso – Monte Curcio” cable car, located in Camigliatello Silano, within the Municipality of Spezzano della Sila and the heart of the Sila National Park, was successfully carried out to bring the system into compliance with current safety and regulatory standards and to guarantee its efficiency and reliability for the next five years.

The intervention included comprehensive structural and mechanical inspections on both civil structures and metal works, as well as the revision and replacement of mechanical and electrical components. The braking system was fully updated, and non-destructive testing (NDT) was performed to verify the integrity of critical parts. A major milestone was the replacement of the carrying-hauling rope, ensuring continued performance and safety in line with industry standards.

In addition, all necessary adjustments required by the Operating and Maintenance Manuals were implemented, including the integration of new technical specifications. To support these works, a complete set of technical and project documentation was developed, including technical reports, control plans, photographic surveys, and risk assessments (covering fire, landslides, and avalanches), along with updated operational manuals.

The intervention was formally approved by the Operations Director, confirming its suitability to ensure safe and continuous service for the next five years — a key achievement in preserving vital public transport infrastructure within one of Italy’s most iconic natural areas.

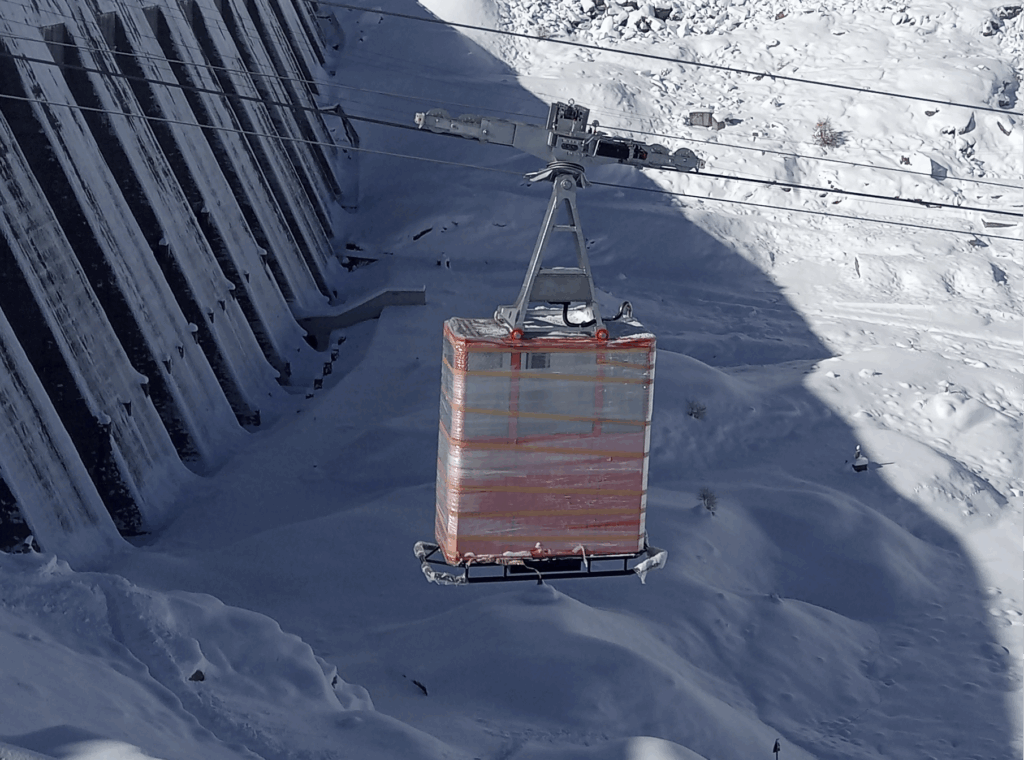

Overhaul of the GRAN SASSO Cable Car

Revitalization of the Gran Sasso Cable Car (RB02)

The five-year overhaul and functional revitalization of the bi-cable “Fonte Cerreto – Campo Imperatore” cable car—also known as RB02—was successfully completed in compliance with D.M. 203/2015, with the objective of ensuring operational continuity and safety until the next scheduled general overhaul in 2028.

The intervention focused on the replacement and inspection of key mechanical, electrical, and hydraulic components subject to wear, along with thorough non-destructive testing (NDT) on structural elements and critical systems, to guarantee the continued efficiency and safety of the installation.

Several targeted interventions were carried out, including: – Repositioning of the carrying ropes – Update of buffers – Rebalancing of vehicles – Enhancement of the ballast rope – Complete overhaul of all technical subsystems, including drives, brakes, trolleys, suspensions, and electrical systems –

Thanks to optimized planning and execution, the entire operation was successfully completed within 60 days, and concluded with the issuance of all required compliance certifications.

This revitalization marks a key milestone in the lifecycle of the Gran Sasso cable car, ensuring safe and uninterrupted service for the next five years, and reaffirming its strategic role in connecting the valley to the high-altitude station of Campo Imperatore.

General Overhaul of the “Forcella – Selva Val Gardena” Cable Car

In 2023, the general overhaul of the “Forcella – Selva Val Gardena” fixed-grip cable car was completed to align the system with current technical regulations and ropeway safety standards. The intervention involved a full inspection and overhaul of mechanical, electrical, and hydraulic components, including the gear reducer, motors, braking systems, and hydraulic unit at the drive-tensioning station. A new sheave and updated cabin guide system were installed at the return station. Across the line, rollers, towers, and cabins were inspected and refurbished, with checks on clamps, suspension arms, structures, and anti-derailment devices. The carrying-hauling rope underwent magneto-inductive and visual testing, while electrical control and safety systems were updated, including preparation for future automation upgrades. The project preserved the cable car’s original design while ensuring safe, efficient, and reliable operation for the years ahead.

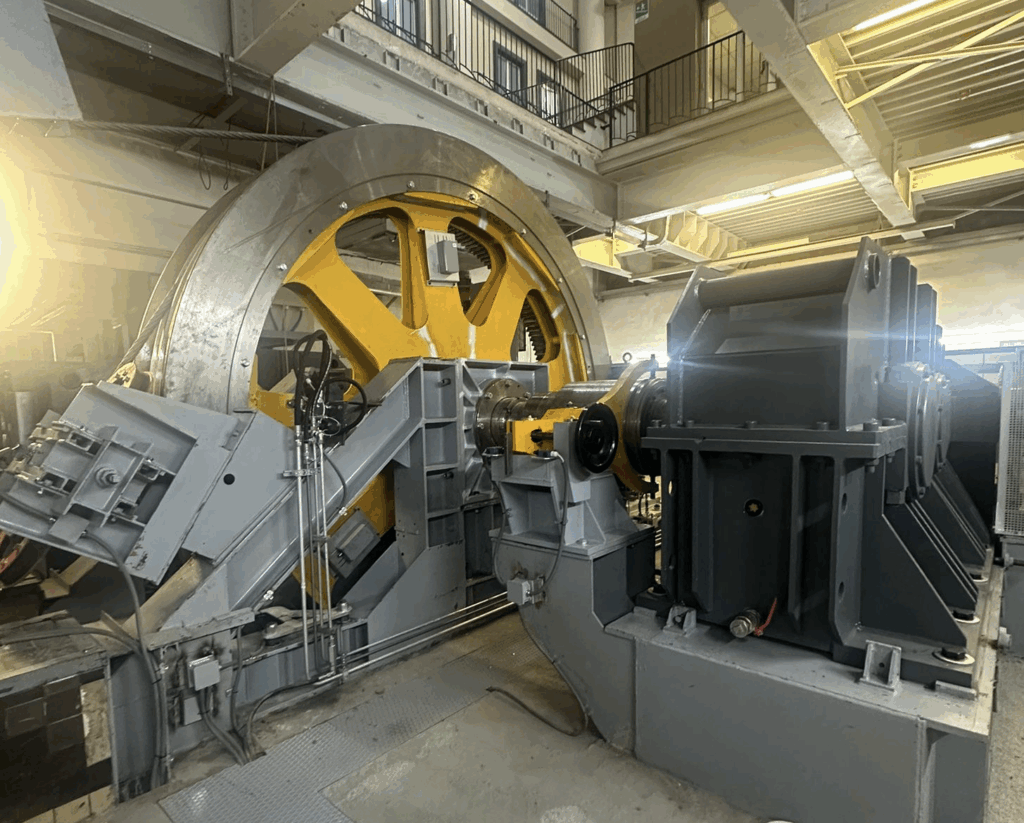

General Overhaul of the “Rigolor – Cima Panarotta” Chairlift

In 2023, the twenty-year general overhaul of the “Rigolor – Cima Panarotta” four-seater chairlift was completed at the Panarotta 2002 ski resort (Municipality of Pergine Valsugana / Frassilongo, TN), in accordance with D.M. 203/2015. Built by Graffer in 2002, the system spans 1,256 meters with a 417-meter vertical drop and a capacity of 1,800 people per hour. The intervention involved a full inspection and overhaul of all mechanical, electrical, structural, and safety systems. Key components such as the 310 kW main motor, 235 kW recovery motor, braking systems, gear reducer, drive and return sheaves, line rollers, clamps, and hydraulic circuits were serviced or replaced. Non-destructive testing was performed on stations, towers, and vehicles, while the 42 mm Redaelli carrying-hauling rope underwent magneto-inductive testing. The electrical and safety systems were fully revamped with updated panels, signaling devices, and PTS-compliant protections. Structural elements, including concrete foundations and grounding systems, were also tested. Following final checks and documentation updates, the chairlift was returned to full public operation, ensuring safety, efficiency, and operational continuity for the next cycle of service.

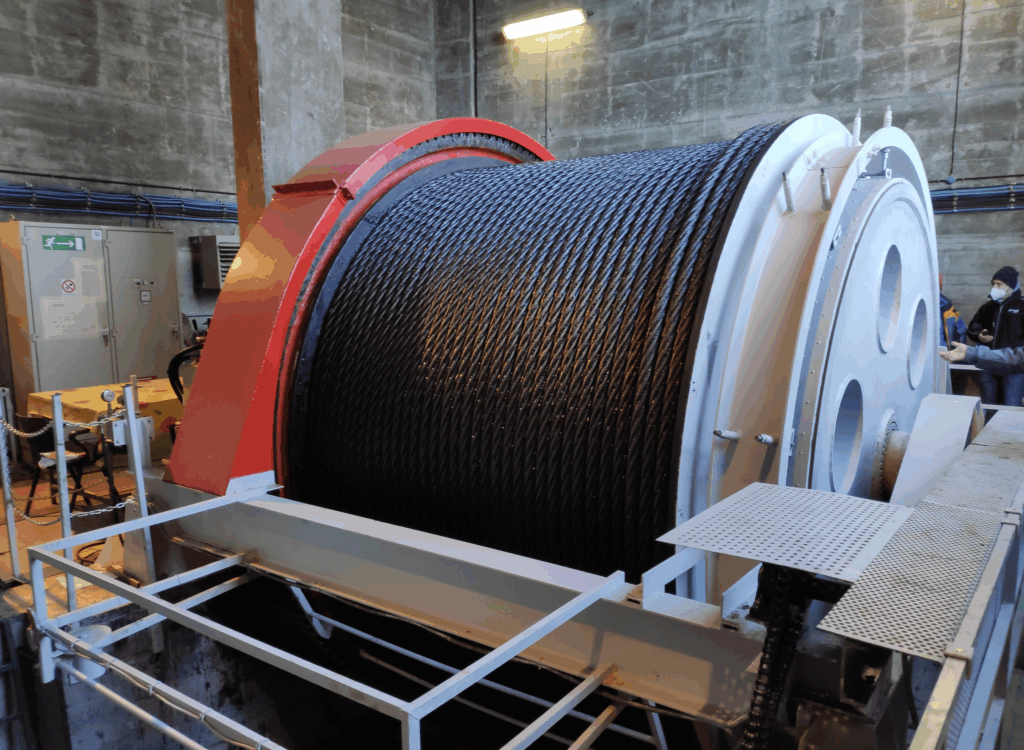

General Overhaul of the ENEL Inclined Lift “Campolongo – Colombé”

The general overhaul and technical modernization of the ENEL inclined lift “Campolongo – Colombé”, located between the S. Fiorano power station and the valve chamber near Lake d’Arno (Municipality of Pratovecchio Stia, AR), was successfully completed in full compliance with D.M. 203/2015 and the latest technical sector standards. Originally built between 1970 and 1971 and previously updated in 1998, the system—measuring 1,825 meters in length with a 1,035-meter vertical drop and a 28-ton capacity—underwent comprehensive refurbishment. The intervention included the replacement of the electric motor, full revamping of electrical panels, and upgrades to control, supervision, and command systems. Key components such as the brakes, gear reducer, drum, and hauling rope were revised, while non-destructive testing was carried out on rollers, pulleys, supports, the vehicle, and the structure. The vehicle itself was overhauled with a focus on the emergency braking system, safety devices, and comfort features for ENEL personnel transport. New event logging, safety systems, and supervision stations were installed, restoring the system to full operational efficiency and ensuring safe, reliable service for internal ENEL operations.

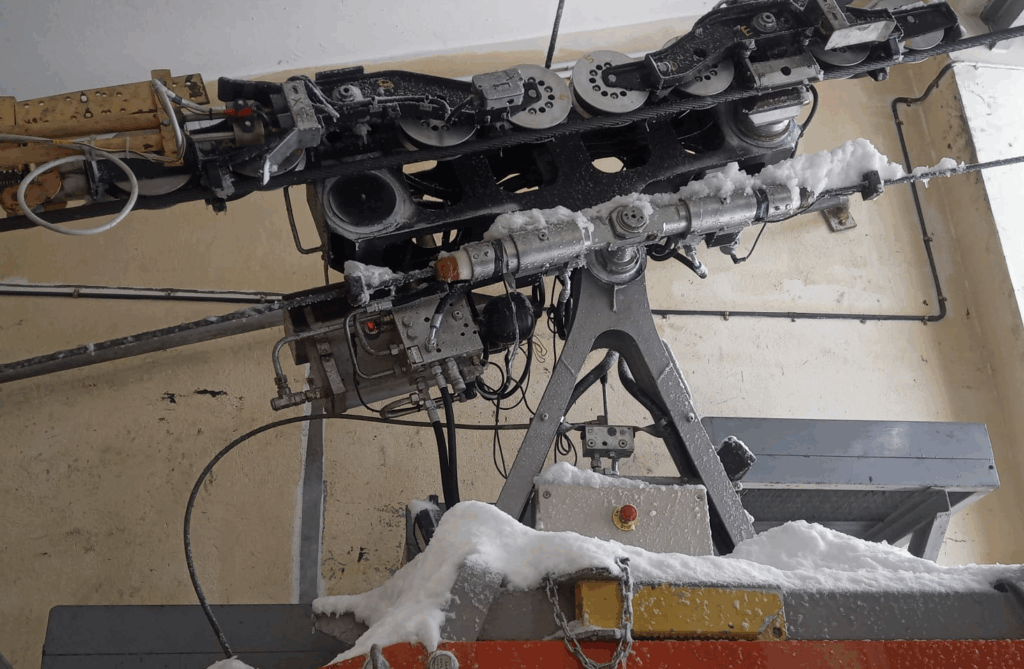

General Overhaul of the ENEL Cable Car “Campliccioli–Crestarossa”

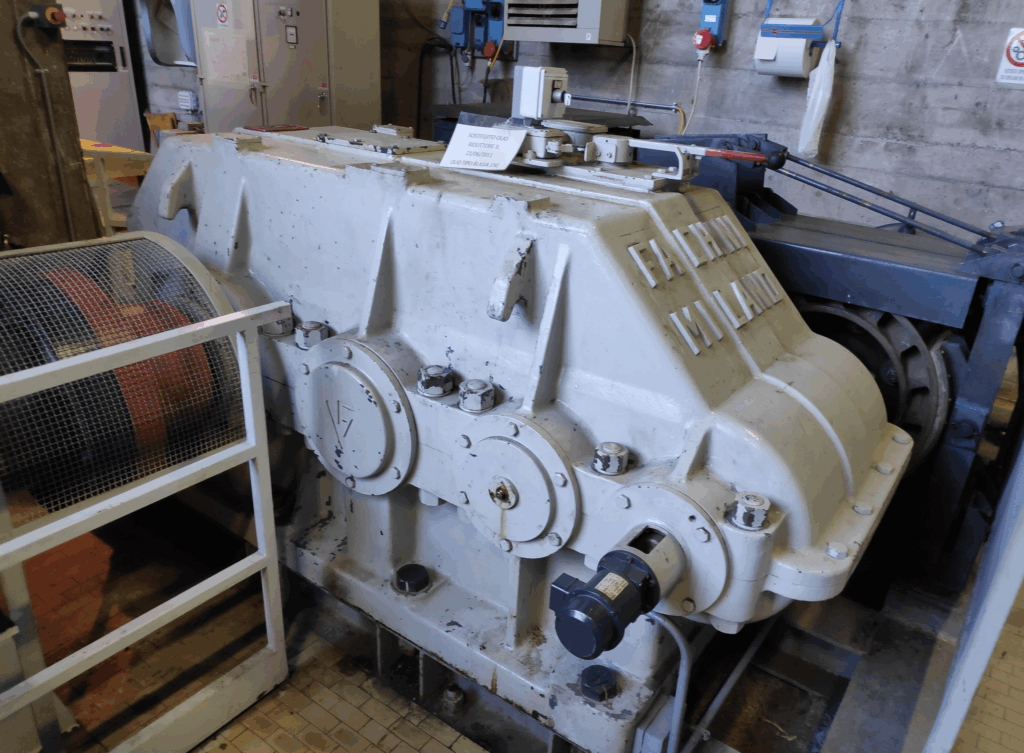

The general overhaul of the bi-cable “Campliccioli–Crestarossa” cable car, originally built in 1969 and last modernized in 2003, is underway to restore full operational efficiency and safety in accordance with technical standards and ENEL’s internal requirements. Used for transporting personnel and materials to the Cingino dam, the system has performed approximately 5,000 trips over the last 20 years. The intervention includes non-destructive testing (NDT) on structures and mechanical parts, the complete overhaul of station equipment (motors, brakes, pulleys, gear reducers, hydraulic units), and inspection and revision of line components, including roller disassembly, and replacement of bolts and bushings. Vehicles will be fully overhauled in the workshop, while additional works involve civil structure maintenance, renewal of safety signage, modernization of electrical systems, and verification of rope anchoring. Previously replaced elements—such as the carrying, hauling, and telephone ropes—are excluded from this contract. The project is carried out in collaboration with original manufacturers (POMA, EEI, EAG, RVS) to ensure technical compatibility, and will conclude with a technical-functional testing phase led by the Works Director and Operations Director.

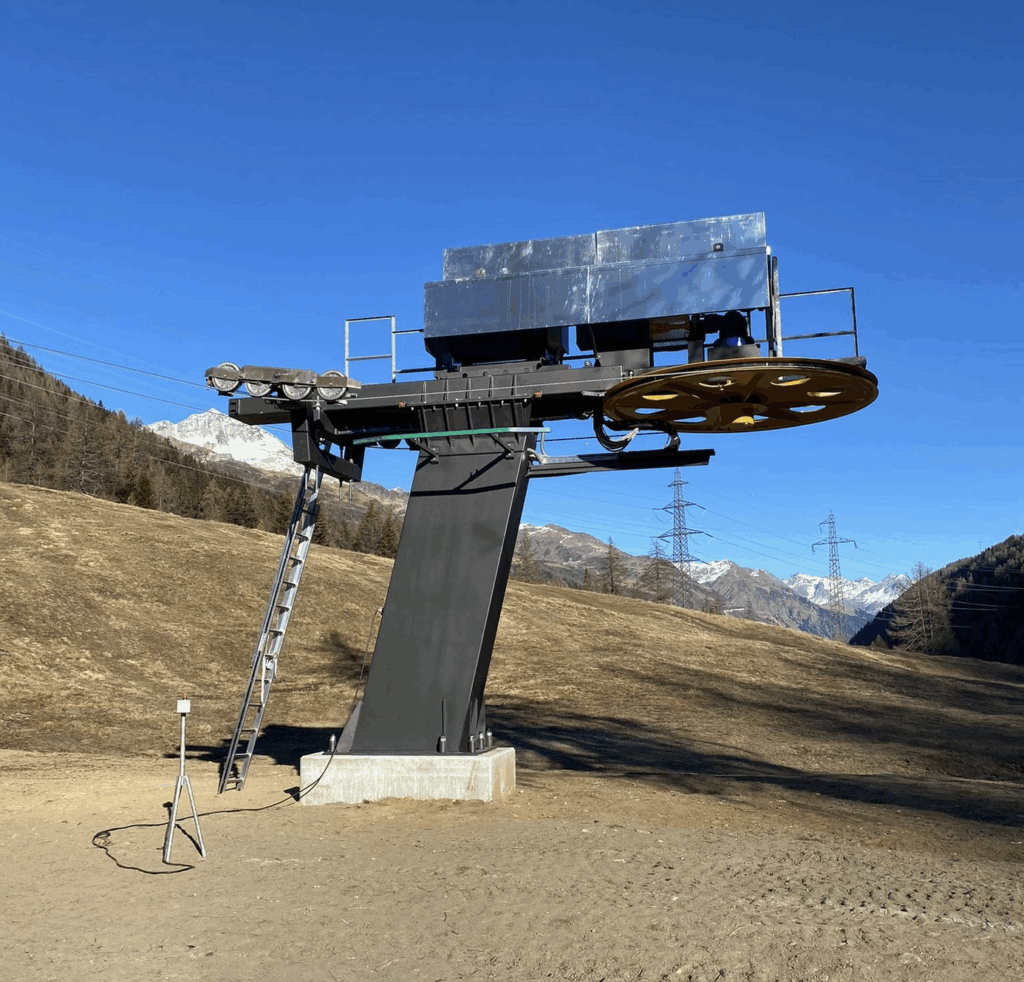

General Overhaul of the REGIONAL Cable Car “Buisson–Chamois”

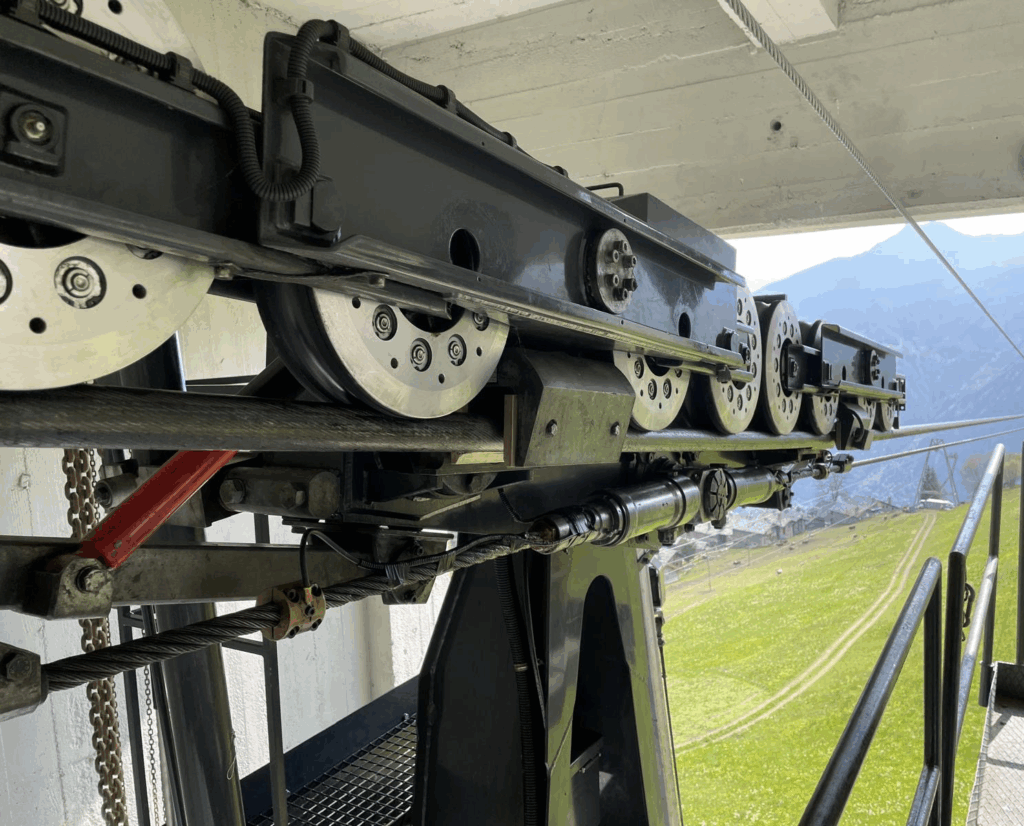

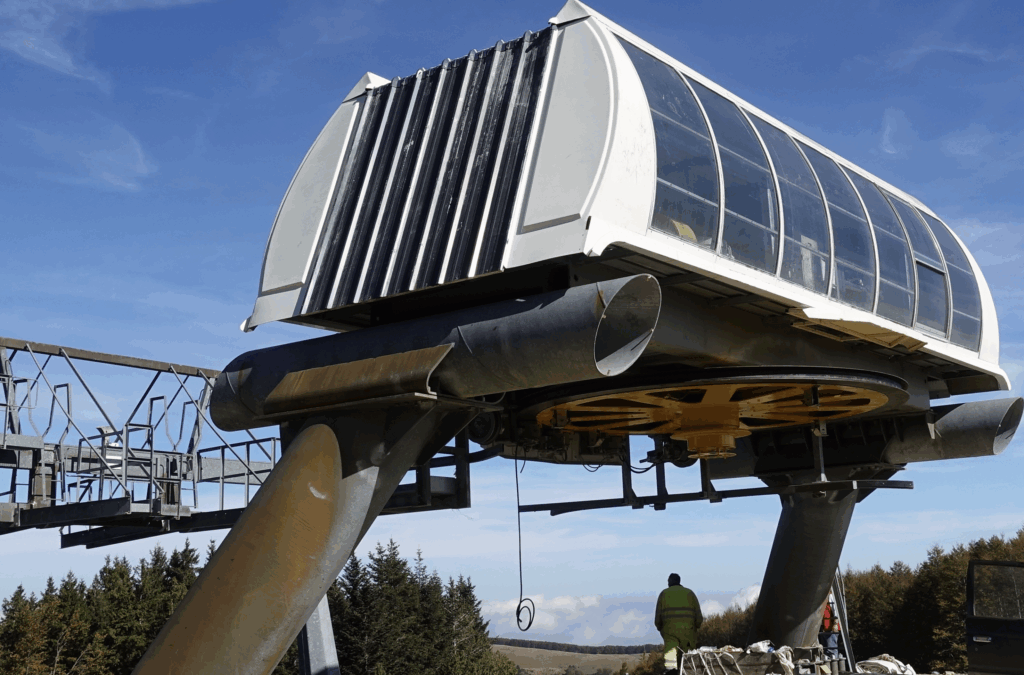

In 2021, the general overhaul of the bi-cable “Buisson–Chamois” cable car (KB14), located in the Aosta Valley and operated by the Autonomous Region, was successfully completed to ensure compliance with D.M. 203/2015 and EU Regulation 2016/424. Connecting Buisson (1120 m) to Chamois (1812 m), the system underwent a full twenty-year maintenance program that included non-destructive testing on major structures, a complete overhaul of pulleys, brakes, winches, trolleys, and suspensions, as well as replacement of the ballast rope and carriage ropeheads, rope movement, and carriage renewal. The electrical, pneumatic, and hydraulic systems were updated, including motors, gear reducers, generators, and the braking system. Both cabins were structurally and functionally upgraded, with new glass panels, opening mechanisms, accessibility features, and internal systems. A modern control and supervision system was installed, featuring CE-certified panels, redundant safety PLCs, remote control, in-line video surveillance, and two-way communication. Additional interventions included line support restoration, lifting hoist replacement, buffer modernization, and regulatory adaptation for unattended operation. The project concluded with final testing and technical documentation updates, ensuring continued safe, reliable public service with a technologically upgraded system.

Overhaul of the MARGNO Cable Car – “Pian delle Betulle”

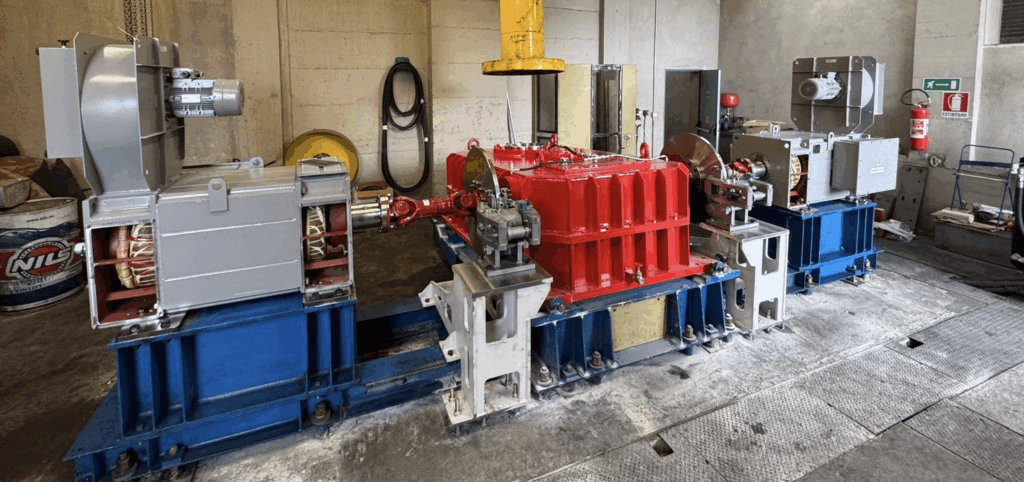

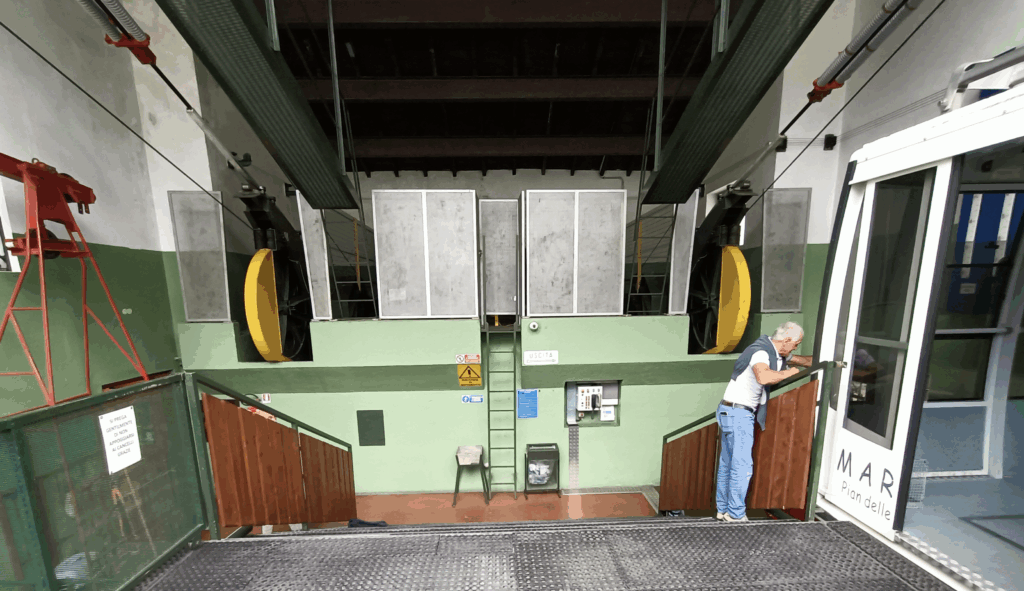

The general overhaul and modernization of the “Margno – Pian delle Betulle” bi-cable aerial tramway, originally built in 1969 in the Municipality of Margno (LC), was planned and approved through a comprehensive executive project, with works scheduled across three phases between 2021 and 2022. The intervention addressed the mandatory five-year and twenty-year inspections required by Ministerial Decree 203/2015, focusing on the replacement of outdated mechanical and electrical components such as the generator set, transformer, main and auxiliary winches, and the braking system. Structural and regulatory upgrades were also planned for both stations, including roof replacements, technical rooms, and access paths. The project included the replacement of the haul rope and carriage ropeheads, as well as the supply of two new rescue cabins, maintenance platforms, elastic bumpers, and improved safety protections. The electrical and safety systems were upgraded to comply with current ropeway and workplace safety standards, ensuring the continued public operation of the system under maximum safety and efficiency conditions.

Relocation of the Overhauled Chairlift “Topolino–Ovindoli”

The technical overhaul and relocation of the “Topolino” four-seater ski lift—a platter lift with a looped carrying-hauling rope—was successfully completed, combining modernization with improved alignment and compliance to current regulatory standards. The new installation, featuring an inclined length of 248.72 meters, a vertical drop of 41.40 meters, and 6 line towers (5 support and 1 hold-down), now delivers an hourly capacity of 1,800 people with 34 vehicles at an operating speed of 2.0 m/s. The hydraulic tensioning system at the bottom station and the drive system were inspected and upgraded, reaching a peak power of 90 kW, while maintaining the efficient 180° rope wrap around the drive sheave. The relocation of the lift resulted in improved load distribution and better integration with the surrounding ski slopes, enhancing both performance and safety for users.

Relocation of the Overhauled Chairlift “Belladonna–Lamaccione”

The overhaul, technical upgrade, and relocation of the “Lamaccione” ski lift were successfully completed to improve efficiency, terrain integration, and regulatory compliance. The project involved repositioning the route, optimizing the elevation profile and tower spacing to enhance operational performance and alignment with the surrounding ski slopes. The main drive system was upgraded with a SICME NP 280 KS-PVA/B3 electric motor rated at 319 kW, delivering 88.6% efficiency, and exceeding power requirements with 177.83 kW at full load and 215.97 kW at startup. The recovery system was equipped with a VM SUN 6105 TE diesel engine (116 kW) and a high-pressure hydraulic system featuring a POCLAIN MS50_0 motor, P35 brake, and REXROTH A4VG 90 pump rated for up to 450 bar. The new configuration significantly enhanced the lift’s accessibility, safety, and compliance with current technical standards, ensuring reliable operation in its updated setting.

Relocation of the Overhauled Chairlift “Capanno–Colere”

The general overhaul and relocation of the two-seater “Capanno” chairlift, located in the Municipality of Colere (BG), has been successfully completed, restoring full operational status in compliance with current safety and technical regulations. The intervention preserved the original configuration while upgrading mechanical, electrical, and structural components. The system features an inclined length of 459.74 meters, a vertical drop of 162.60 meters, 7 line towers, a transport capacity of 1,183 people/hour, and operates at 2.5 m/s with a 3-minute travel time. The carrying-hauling rope (Redmont 636, Ø 42 mm) was inspected and refurbished, and the 300 kW drive motor with hydraulic tensioning was retained. The relocation also included the installation of underground fiber optic and multipolar copper connections between stations, and full compatibility with the existing ski slopes was verified. The lift is now authorized for both daytime and nighttime skier transport, fully meeting updated safety, reliability, and service standards.

Turnkey Project – New “Prada-Costabella” Basket Lift

GRAFFER designed and constructed the new “Prada–Costabella” basket lift, a fixed-grip two-seater system developed entirely with new components and safety devices. The installation features a bottom return station with hydraulic tensioning and a fixed top drive station, both constructed with steel structures and equipped with maintenance walkways, access stairs, enclosures, and integrated safety systems. The hydraulic tensioning system includes an alarm and control unit to ensure safe and stable operation.

The lift is equipped with fixed forged-steel grips, two-seater carriers approved for the transport of disabled passengers and bicycles, and anti-derailment roller assemblies to enhance safety along the line. A comprehensive suite of signaling and safety systems, along with differentiated braking systems—electric, mechanical, and hydraulic—ensures maximum operational reliability. The electrical control and supervision panel provides full monitoring and system management. To support ongoing operations, rescue and maintenance equipment, including service trolleys and spare parts kits, are also supplied.

The executive design, managed entirely by GRAFFER, includes structural verifications, technical drawings, and compliance documentation for approvals by ANSFISA and DTT. Fully aligned with current regulations, the project guarantees high standards of reliability, accessibility, and safety, contributing to the efficiency of local public transport services.

Complete Overhaul of the ENEL Cable Car “Pantano”

The modernization of the ENEL “Pantano” bi-cable cable car was a comprehensive project focused on enhancing safety, operational efficiency, and regulatory compliance. The intervention began with dismantling operations, which included non-destructive testing on the line towers and stations, deactivation of the electrical system, and the removal of key components such as the drive and return stations, line rollers, vehicles, and tensioning ropes.

Subsequent on-site revisions were carried out on the suspension systems, pulleys, winches, hydraulic units, and buffers, ensuring optimal functionality and long-term reliability. At the same time, new components were manufactured and installed, including custom-designed cabins, electrical equipment, corrected tower alignments, and safety protections along the line—guaranteeing full compliance with current safety standards.

The reassembly phase featured the installation of modernized stations, updated vehicles, refurbished line components, and new tensioning ropes, along with an upgraded electrical system. Special attention was given to the control panels, which were modernized to enhance system performance and monitoring.

In the final phase, the line towers were repainted, electrical wiring was completed, and the entire system was integrated and tested. Internal trials and final certification confirmed that the cable car now meets all operational and safety standards, ensuring its continued use for ENEL’s personnel transport needs with improved reliability, efficiency, and technical integrity.

Overhaul of the ENEL Cable Car “Grumetti–Barbellino”

The complete maintenance and modernization of the ENEL “Barbellino” cable car focused on improving safety, efficiency, and system reliability through a series of targeted upgrades. The intervention included a full overhaul of the main operating system and emergency brakes, as well as the inspection and modernization of hydraulic units and high-altitude piping to extend their service life. The gearbox, along with both the recovery and emergency winches, underwent detailed inspections and complete overhauls, including their hydraulic systems and piping. A thorough revision of the vehicle, suspension trolley, and cabin was carried out to restore structural integrity and passenger comfort, while the trolley brake hydraulic unit was upgraded for improved response. The electrical control systems and wiring were also brought up to current safety standards. Additional work included maintenance and refinishing at the lower station and on the line towers, with cladding replacement on the third tower. Line and emergency rollers were inspected, refurbished, and fitted with new rings where necessary, and precise adjustments were made to ensure proper movement and alignment of the carrying cables, reducing wear and extending system life. A spare parts inventory was also replenished to support long-term maintenance. The final phase included commissioning, internal testing, and safety certification, confirming full regulatory compliance and delivering a safe, high-performance installation ready for continued operation.

Relocated and Refurbished SKI LIFT “Ciossprato”

Overhaul and Relocation of the “Cioss Prato” Single-Seater Ski Lift:

Located in Bedretto, Switzerland, the lift—operated by MEB Impianti—was relocated to a new alignment with technical upgrades and updates to mechanical and electrical components.

The line, approximately 237 meters long with a vertical drop of 50 meters, features 3 towers and 40 self-service platter carriers, with a capacity of 600 people per hour.

The drive system uses a 15 kW variable-speed DC motor with automatic hydraulic tensioning, and the drive station is located at the bottom.

The project included a full overhaul of the system, non-destructive testing, supply and splicing of a new rope, preparation of the executive design, updates to technical documentation, and final on-site reassembly.

The installation is now compliant with current Swiss regulations.

Stay informed about our latest projects, innovations, and industry milestones — follow us on LinkedIn for real-time updates and behind-the-scenes insights.

👉 Follow us on LinkedIn and be part of our journey..

📧 [email protected] | 📞 +39 030 910 3427